3D Printer Filament Is Stuck

Filament can swell inside the extruder and get stuck.

If you cannot unload filament from one of the extruders, do the following:

1. On the LCD panel, navigate to Utilities > Change Filament > Unload. This option heats the extruders.

- Jul 18, 2018 4:13:58 PM

- Posted by Anna Sandler

- Topics: MakerBot, 3D-Printer

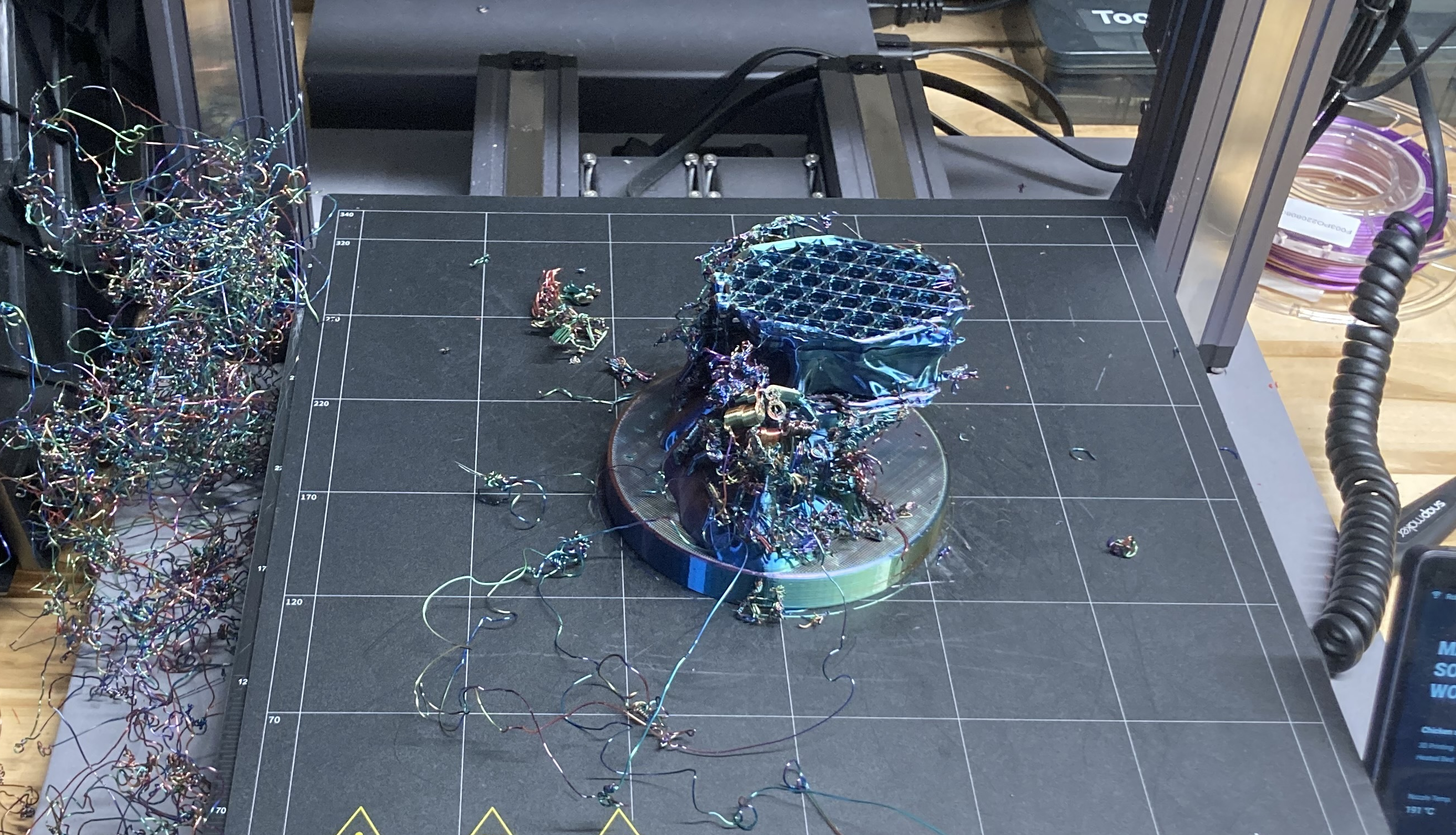

How to 3D Print With The Most Quality Guide

Cracks, Warping, Rippling, Drift... Tips to help your projects look their best on the very first try.

- Jul 18, 2018 2:42:50 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

3D Printer Safety Instructions

Dos and don'ts

- Jul 18, 2018 2:25:10 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

3D Printer Filament Not Loading

If you are having problems loading filament into one of the extruders, perform the following steps:

1. Using the LCD panel, navigate to Utilities > Filament Options > Unload. This option heats the extruders.

2. Make a fresh cut at the end of the filament. It is important that the filament have no bends in it. If there are bends, cut off the bent section of filament.

3. Insert the filament into the hole at the top of the extruder. Keep pushing it in until you start to see plastic come out of the nozzle.

You might have to apply some pressure.

4. When the filament is successfully loaded, set the extruder lever arm to the closed position.

- Jul 18, 2018 2:04:43 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

3D Printer Replicator Shakes

Your MakerBot Replicator will shake during printing if you print at high speeds with acceleration turned off.

Attempting to print at high speeds with acceleration turned off can harm your MakerBot Replicator.

To check and change the Acceleration setting, go to the LCD menu on your Replicator MakerBot 2X and navigate to Info and Settings > General Settings > Accelerate.

You can turn acceleration off and on. Acceleration is turned on by default. If you have acceleration turned off, you should not print at speeds above 40 mm/s.

- Jul 18, 2018 2:01:41 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

3D Printer Extrusion Stops

There are a few problems that can cause your MakerBot Replicator to stop extruding. Use this checklist to determine the cause and appropriate solution.

- Jul 18, 2018 1:59:17 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

3D Printed Objects Are Difficult to Remove from the Build Plate

If printed objects are difficult to remove from the build plate, try these solutions:

• Wait for the build plate to cool down. Objects will detach more easily when both the plastic and the plate are cool.

- Jul 18, 2018 1:53:14 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

3D Printed Objects Do Not Stick to the Build Plate

If printed objects are not sticking to the build plate, try these solutions:

- Jul 18, 2018 1:42:21 PM

- Posted by Anna Sandler

- Topics: Troubleshooting & Warranties, MakerBot, 3D-Printer

Email Support

Email Support

If you’re unable to find an answer on our website, fill out the form below to start a ticket. We normally aim to respond to all emails within a few days.

Call-in support

Call-in support

Our support engineers are standing by to help.

+1 (415) 702-3033-

I Want To Learn MoreADDITIONAL INFORMATION

Email Support

Email Support Call-in support

Call-in support