Signs your Warehouse Environment Needs Mobile Robots

Dec 14, 2020

By Justin Osborne

Photo by CHUTTERSNAP on Unsplash

Photo by CHUTTERSNAP on Unsplash

Although the term automation has a very wide meaning and covers several areas, in general, it's a technology with minimized human involvement. It includes different types of processes and procedures, depending on the level of complexity, and the specific industrial or home surroundings. For example, a smart boiler thermostat is the simplest form of home automation.

Robotics develops, designs, and constructs machines to assist people. Robots are particularly useful in replacing humans in life-threatening situations and environments. Manufacturing procedures involving hazardous materials, with human activities that can be replicated by machines, are ideal for the use of industrial robots.

Regarding the expansion of robotics

Educational robotics aims to help students develop their skills by engaging in designing robots. Robotics is a great industry for young people. Besides being able to directly interact with new technologies, they are also able to work on its further development with fresh ideas and solutions. Some foundations and organizations are offering scholarships in the STEM field and Data science for students who are particularly interested in these subjects. Since there is no second chance with application and writing scholarship essays is not that easy, students can hire a scholarship essay writing service. A professionally written scholarship essay helps to avoid some common mistakes which are often a result of pressure and lack of experience. With this type of assistance, students can significantly increase the odds of winning financial aid.

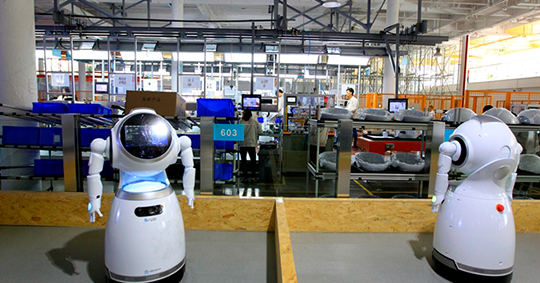

Warehouse Robotics

Large companies, such as Amazon, with a wide range of products, around the globe delivery option and complex logistic scheme composed of hundreds or thousands of facilities and various centers, often use robots to stay operational. Imagine picking numerous packages, reading barcodes, and sorting them by the ZIP code all by hand in an extremely large warehouse. Autonomous mobile robots (AMR) are designed to complete various tasks and move through the warehouse, without constant human supervision. Unlike magnetic tracks, AMR uses sensors and read maps to recognize the obstacles and avoid them. These machines transform operations such as storing and transporting goods and materials. Here, we give you three signs that your warehouse needs these mobile robots.

Transport time

In most warehouses with old school type of organization the communication between different parts, such as sorting and picking areas, employers have to walk or drive many times, back and forth, in order to pick items and ship or load them. This could be extremely time-consuming which also affects shipping time, logistic costs, and overall inventory management. If goods are sitting in the warehouse longer than needed, it means that the company needs AMR.

These robots can speed up the picking time up to 2 or even 3 times. They can also pick items for several orders and, if necessary, distribute them to the different areas of the warehouse using the fastest and most efficient routes. This reduces the number of accidents and possible mistakes, as well as transport time through the warehouse. Introducing mobile robots in such a manner can help to strengthen the supply chain and avoid additional pressure on people who work there.

Expenses for traditional warehouse equipment

In order to prevent injuries, damages, and to save valuable time warehouses are using different kinds of traditional equipment such as forklifts, hand trucks, service carts, pallet jacks, cranes, and castors. If a company has warehouse safety issues while handling goods maybe it's time for robots. Because these machines can cover a large surface of the facility with extreme efficiency the inner traffic jam can be completely avoided. Some robots can replace several different types of equipment and therefore save a significant amount of money reserved for maintenance.

Warehouse expenses

This is probably the best argument for using AMRs. If a warehouse faces problems with high expenses then AMRs can be a good solution. To deploy them, a company doesn't need to make large and expensive infrastructural changes. Because AMR has the ability to navigate through the facility, there is no need for magnetic strips, specially arranged parts, or any kind of human involvement in the areas where AMR has been deployed. Also, they can easily be moved from one area of the warehouse to another or completely different facilities.

Conclusion

Robots are already present in our houses and companies. It's great to be able to do something else because our robot vacuum cleans for us. In Korea, robots provide basic services for elderly people in nursing homes with their daily routine, such as assistance with getting out of bed and carrying. Meanwhile, restaurants in Japan use them in the kitchen for repetitive motions. Robots are already a part of the hospitality and food industry as receptionists, waiters, and rice planters. Obviously, companies can have many benefits from using mobile robots in their warehouses as they proved to be useful.

Discover more about Industrial Robots with RobotLAB!

Author bio:

Justin is a marketing specialist and blogger from Leicester, UK. When not working and rooting for Leicester FC, he likes to discuss new trends in digital marketing and share his own ideas with readers on different blogs and forums. Currently, he is working as a content marketer at scholarship essay writing service.

Too much to read? Don't have time?

Too much to read? Don't have time?

.webp?width=124&height=124&name=image%20(1).webp)

.webp?width=169&height=87&name=image%20(2).webp)