4 Ways Robots Are Making Construction Safer

Nov 18, 2020 By Natalia Galvis

By Kurt Walker

Photo by Gus-Angelo Orozco on Unsplash

Photo by Gus-Angelo Orozco on Unsplash

A lot of industries expose workers to hazardous situations, but none more than the construction industry. It is by far the most dangerous occupation because the very nature of the job is based on all sorts of risky situations and unsafe behavior.

It takes serious strategic planning and investments to protect construction workers from different types of occupational hazards, but most companies fail to oblige and so they leave their employees more or less exposed and vulnerable.

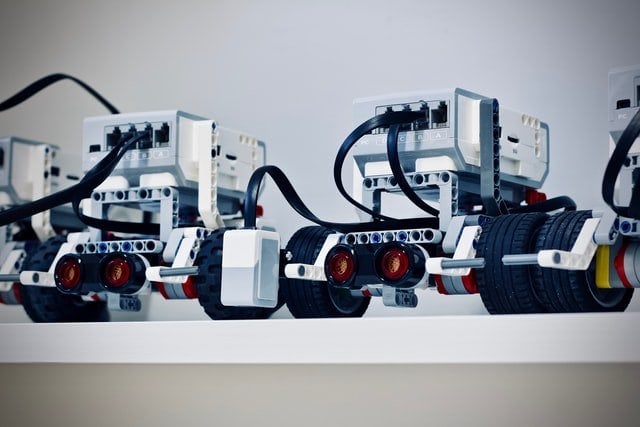

This is where robots step into play to make construction a safer business.

A robot is a machine that resembles a living creature in being capable of moving independently (as by walking or rolling on wheels) and performing complex actions (such as grasping and moving objects). As such, robots can assist human workers in construction projects and take over the corresponding risks.

In this article, we will explain what makes construction works so dangerous and show you four ways robots are making this industry safer. Let’s check it out!

The Dangers of Working in the Construction Industry

It may seem a bit too obvious, but we have to discuss the threats of working in the construction industry because it comes with so many risks and obstacles. It’s not like running an assignment help or thesis writing service – on the contrary, construction is an outdoor job that poses a lot of threats.

First of all, construction workers almost always have to worry about falling from rooftops and similar structures. Fall-related deaths and injuries are frequent, but they are indeed difficult to avoid as it is often impossible to build entirely safe fall barriers and platforms.

Construction works are also risky because employees get in touch with heavy machinery, so they get injured while operating things like cranes or forklifts. Accidents occur because workers are not skilled enough or simply because they become tired and lose focus.

Besides that, working in trenches is extremely dangerous because it demands thorough preparations and emergency plans. In reality, however, lots of teams neglect details such as ramps, emergency exits, and wall support measures.

Bearing all that in mind, it’s not surprising to see that industry reports warn about the dangers of construction works. Here are some of the most important stats and findings:

- Construction is the most hazardous industry since one in five worker deaths occur in this field of work.

- Construction workers accounted for nearly 50% of all fatal work injuries in 2018.

- A construction worker has a 1-in-200 chance of being fatally injured on the job

- The four main causes of construction worker deaths are falls (39%), struck by an object (9.5%), electrocutions (8.6%), and caught-in or between (7.2%).

The danger is real, but what is the role of robots in the process of improving construction worker safety? We will check it out in the next chapter.

4 Safety-Related Benefits of Using Robots on Construction Sites

There are so many ways to use robots on construction sites in order to make workers safer, but we will point out the four main use-cases here.

Heavy lifting robotsHuman workers cannot compete with smart machines when it comes to lifting heavy objects. Robots make heavy lifting a lot faster and safer, so they are becoming the new norm in construction projects. You can find many examples of humanoid robots designed specifically to support construction works through heavy lifting, with HRP-5P being one of the latest inventions in this area.

Demolition robotsRobots still cannot replace professional content creators at SuperiorPapers and AustralianWritings, but they can certainly replace construction workers in demolition tasks. Some of the latest demolition robots are very small and mobile, so it’s even possible to use them for indoor demolition projects.

Robots for repetitive tasksRepetitive tasks are yet another reason why people get injured at work, but there are robots ready to cope with this issue as well. For example, the bricklaying robot SAM can engage in onsite masonry construction and get most of the work done on behalf of traditional construction employees.

Remote operation robotsInstead of working from a bulldozer or crane directly, human operators can now control robots remotely and take workplace safety to a higher level. There are also robots that are almost entirely independent and capable of doing the work with minimal supervision.

According to Freethink, we could soon have a job site on which a single operator is operating up to 10 machines at a time, keeping projects moving around the clock. Although it may sound a bit too futuristic, the process has already started and it is only a matter of time before it becomes fully applicable to daily construction works.

The Bottom Line

Construction is the most dangerous of all industries, so it forces engineers and project managers to constantly create new ways of protecting their employees. The results have not always been too convincing, but the situation might as well change with the introduction of robots to construction sites.

In this post, you could learn the following:

- Features that make the construction industry so dangerous

- Four ways robots are making this industry a lot safer

Although construction-focused robots are still in the early stages of development and implementation, they already proved to be a useful addition to workplace safety, so we can expect the trend to keep taking over the construction industry in the years to come.

Discover more Business Robots with RobotLAB!

Check more information here: https://business.robotlab.com/

Author’s Bio Kurt Walker has been working as an editor and a copywriter at EssayWritingL and in London for three years, where he provides assignment writing service. He is also a professional content writer and journalist and provides assignment help in such topics as inspiration, productivity, education, and technologies.

Author’s Bio Kurt Walker has been working as an editor and a copywriter at EssayWritingL and in London for three years, where he provides assignment writing service. He is also a professional content writer and journalist and provides assignment help in such topics as inspiration, productivity, education, and technologies.

.webp?width=124&height=124&name=image%20(1).webp)

.webp?width=169&height=87&name=image%20(2).webp)