Robotics in fabrication labs provide transformative solutions that enhance the efficiency and precision of manufacturing processes. By automating tasks such as material handling, assembly, and machining, robotic systems minimize manual errors and increase accuracy. These advanced technologies streamline operations, enabling rapid prototyping and iterative design changes, which accelerate development cycles and support flexible manufacturing.

Furthermore, robotics facilitate complex, high-precision tasks that are essential for producing high-quality results. Their real-time monitoring and adaptive capabilities allow for continuous improvement and innovation. By integrating robotics into fabrication labs, organizations can achieve superior outcomes and push the boundaries of manufacturing possibilities, driving both efficiency and creative advancement.

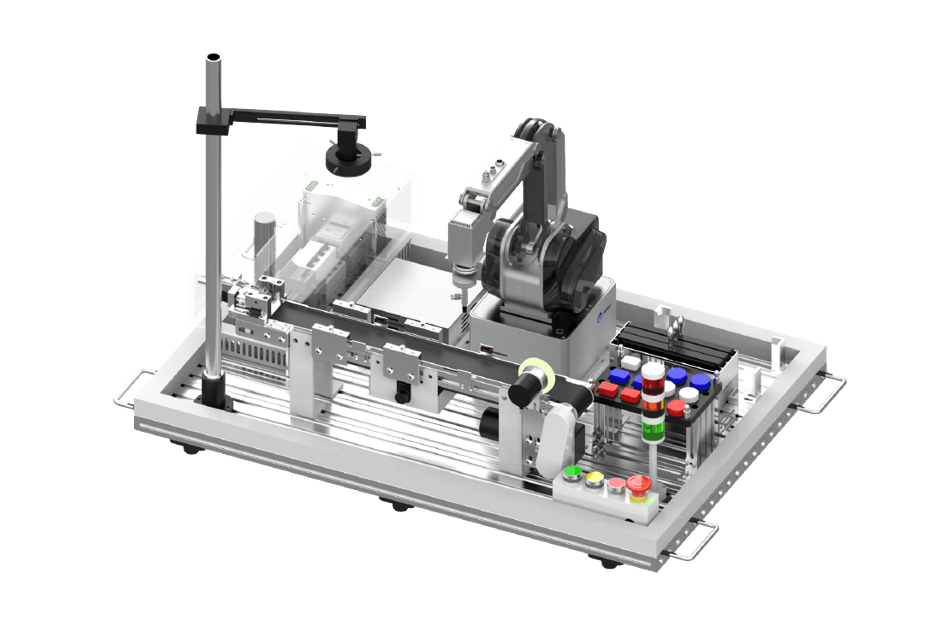

Robotics are transforming high school and university fabrication labs by enhancing precision, efficiency, and flexibility in educational manufacturing processes. These advanced systems automate intricate tasks such as 3D printing, material handling, and assembly, significantly reducing human error and improving accuracy. By streamlining rapid prototyping and allowing for quick iterations, robotics enable students and educators to experiment with design modifications more efficiently, fostering a more dynamic and responsive learning environment.

The integration of real-time monitoring and adaptive technologies ensures continuous improvement, allowing labs to maintain high standards of quality while optimizing workflow. Additionally, robotics empower students to undertake complex projects that would be challenging to achieve manually, pushing the boundaries of creativity and innovation. Overall, robotics are elevating fabrication labs into more efficient, accurate, and cutting-edge spaces, driving advancements in education and hands-on learning in manufacturing and design.

RobotLAB can help you design your Fabrication Lab according to the age group and budget. For example, an elementary Fab Lab may include Makey Makey, Ozobots, Cubelets, and other ready-made products that have more structure, whereas a university-level Fabrication Lab would have more open-ended products, like 3D printers, programmable autonomous robot chassis, or open-source programmable robots. Curriculum or lesson guides are available according to the products chosen to be in a specific Fab Lab and the level of experience that the Fab Lab users have.

Maybe you already have an “AI Lab,” course, or lecture that teaches more traditionally structured STEAM subjects. Fab Labs offer a more creative, hands-on STEAM education that develops critical thinking, problem-solving, and teamwork skills. By providing real-world applications and interdisciplinary learning opportunities, Fab Labs help students apply theoretical knowledge practically and build valuable skills for future careers. Additionally, they encourage adaptability and resilience, preparing students for the challenges of the modern workforce. Overall, Fab Labs enrich the educational experience, creating a dynamic environment that nurtures creative and skilled learners.

Local Service, tailored to YOUR needs!

With RobotLAB, you get more than just robots - you gain a dedicated, LOCAL robotics partner.

We offer comprehensive services including on-site deployment and training, account management, content creation, system integration, and preventive maintenance. Our expert team provides detailed Standard Operating Procedures and cheat sheets to support your staff. With locations nationwide and globally, our sales, service, and repair centers are always nearby.

Affordable Monthly Payments on Robots

Opt for financing to spread out payments, maintain cash flow, and ensure your financial flexibility remains strong.

Our comprehensive financing options simplify the process of bringing a robot to your organization, ensuring affordability and ease. Collaborating with trusted finance partners, we shop for the most competitive rates tailored to your credit profile and unique needs. This ensures you can benefit from manageable monthly payments, bringing advanced robotics technology within your reach without financial strain.

.webp?width=124&height=124&name=image%20(1).webp)

.webp?width=169&height=87&name=image%20(2).webp)

.webp?width=124&height=124&name=image%20(1).webp)

.webp?width=169&height=87&name=image%20(2).webp)

Browse RobotLAB Locations nearby. RobotLAB is expanding nationally and internationally. If you are interested in joining our ever-expanding network of locations, and bring robotics and AI to your local community, please visit our RobotLAB Franchise page.