Tired of risking worker safety with hazardous cleaning or wasting valuable time on manual deliveries? Upgrade your industrial and manufacturing plant with next-generation robots! Our solutions eliminate worker risk by automating hazardous cleaning tasks and boosting productivity with 24/7 efficiency.

Free up your workforce with automated material handling and delivery, unlocking significant production gains. Reduce labor costs and maximize ROI by investing in a clean and efficient work environment powered by robots. Don't miss out on the future of industrial automation – revolutionize your production floor today

Industrial and manufacturing facilities encounter significant challenges related to worker safety, operational efficiency, and cost management. Delivery, forklift and stock chasser robots and cleaning robots directly address these concerns by automating critical tasks. Manual cleaning of hazardous materials and transporting heavy objects pose risks to workers, but these robots minimize human exposure to such dangers. Additionally, traditional methods often lead to wasted time and workflow disruptions.

Delivery robots, acting as efficient material handlers, ensure that materials arrive precisely when needed, keeping production lines running smoothly. Cleaning robots work tirelessly as part of the warehouse picker team, maintaining a consistently clean environment and minimizing downtime.

By tackling safety issues, optimizing workflow, and reducing labor costs robots provide a compelling solution for a more efficient and safer industrial future.

In a manufacturing or industrial setting, robots revolutionize operations by automating key processes and tasks, ensuring enhanced efficiency, safety, and productivity.

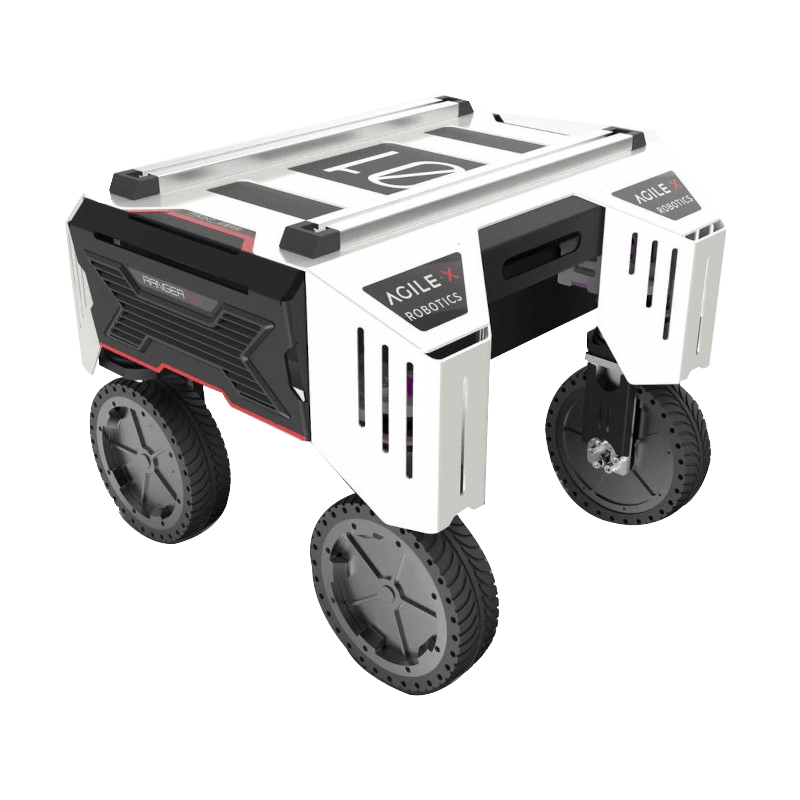

Autonomous forklifts and tuggers are employed to transport heavy materials and goods across the facility with precision and speed, reducing the need for manual labor and minimizing the risk of workplace injuries. These robots can be programmed to follow specific routes or dynamically adjust their paths based on real-time data, ensuring seamless material handling and optimized workflow.

Stock chasers and warehouse delivery robots further streamline operations by swiftly moving smaller items or inventory to designated locations, maintaining an organized and efficient production line. This level of automation not only boosts productivity but also reduces labor costs, allowing human workers to focus on more complex and value-added activities.

Industrial-grade robotic floor cleaners and automated quality control systems play a crucial role in maintaining a clean and safe working environment. These robots ensure that the facility remains spotless by performing regular cleaning cycles, significantly reducing downtime and enhancing workplace sanitization.

By integrating AI-powered warehouse solutions and smart warehousing technologies, businesses can leverage data analytics to monitor performance, predict maintenance needs, and make informed decisions. The implementation of robotics in manufacturing and industrial settings leads to a more efficient, safer, and cost-effective operation, positioning businesses at the forefront of innovation and competitiveness in their industry.

Local Service, tailored to YOUR needs!

With RobotLAB, you get more than just robots - you gain a dedicated, LOCAL robotics partner.

We offer comprehensive services including on-site deployment and training, account management, content creation, system integration, and preventive maintenance. Our expert team provides detailed Standard Operating Procedures and cheat sheets to support your staff. With locations nationwide and globally, our sales, service, and repair centers are always nearby.

Affordable Monthly Payments on Robots

Opt for financing to spread out payments, maintain cash flow, and ensure your financial flexibility remains strong.

Our comprehensive financing options simplify the process of bringing a robot to your organization, ensuring affordability and ease. Collaborating with trusted finance partners, we shop for the most competitive rates tailored to your credit profile and unique needs. This ensures you can benefit from manageable monthly payments, bringing advanced robotics technology within your reach without financial strain.

.webp?width=124&height=124&name=image%20(1).webp)

.webp?width=169&height=87&name=image%20(2).webp)

.webp?width=124&height=124&name=image%20(1).webp)

.webp?width=169&height=87&name=image%20(2).webp)

Browse RobotLAB Locations nearby. RobotLAB is expanding nationally and internationally. If you are interested in joining our ever-expanding network of locations, and bring robotics and AI to your local community, please visit our RobotLAB Franchise page.